1.Dimensions:

Internal Dimensions: The inner space of the packaging.

External Dimensions: Includes the size of the packaging material.

Product Dimensions: The outer size of the product to be packaged.

Product with Tray Dimensions: Product size plus the tray. Specify the product size, tray size, material type, and thickness.

Provide the actual product to the factory for accurate sizing since design drawings are critical. Real products allow for trial fitting and packaging size adjustments. Depending on the situation, some extra space can enhance the design.

2.Materials:

Kraft Paper: Raw paper with a texture, available in brown and white. Brown kraft paper feels eco-friendly but has poorer color accuracy and is unsuitable for lamination.

Single-side Coated Paper: Coated on one side for high print quality, used for single or low-requirement double-sided printing.

Double-sided Coated Paper: Coated on both sides, used for high-quality double-sided printing.

Metallic Paper: Coated with gold or silver, used for high-end packaging like cosmetics and gift boxes.

Grey Board: Ranges from 800gsm to 2000gsm, used for rigid packaging like gift boxes.

Corrugated Paper: Used for shipping boxes and protective inserts, providing rigidity and cushioning.

3.Box Types:

Card Boxes: Made from card stock, foldable, ideal for minimizing packaging.

Book-style Boxes: Open like a book, often with magnetic closures, used for gift packaging.

Folding Boxes: Book-style boxes that can fold flat to save space.

Drawer Boxes: Feature pull-out drawers, made from grey board and double-sided coated paper.

Shipping Boxes: Made from corrugated paper, flat before assembly, used for transport.

4.Inserts:

Paper Inserts: Economical and eco-friendly.

Blister Inserts: Made from PET or PVC, suitable for irregular products.

EVA Inserts: High-density, protective, ideal for high-end products.

EPE Inserts: Low density, protective, more economical and eco-friendly than EVA.

Fabric Inserts: Adds a layer of fabric for aesthetic enhancement.

5.Windows:

Partially expose the product with a transparent film or leave it open for an eco-friendly option.

6.Techniques:

Hot Stamping: Adds metallic effects, often for logos or patterns.

UV Coating: Clear and glossy, enhances design on matte surfaces.

Embossing/Debossing: Adds texture and tactile interest.

Embossing: Adds texture, enhances brand perception.

Dull Polish: Adds a rich feel and protects the print.

7.Printing:

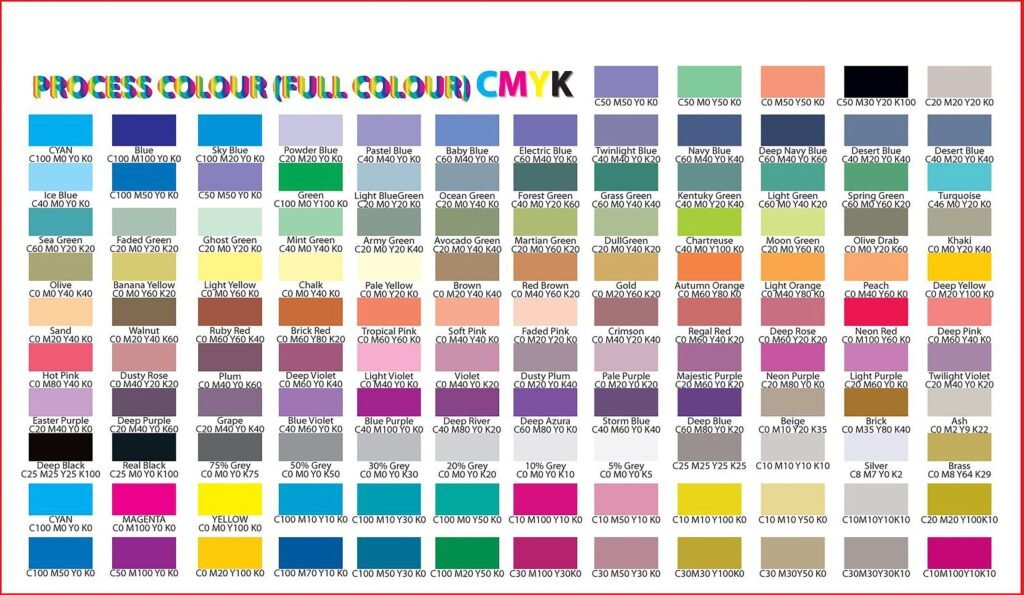

CMYK: Uses cyan, magenta, yellow, and black inks to create various colors. Recommended for standard printing.

Pantone: For precise colors not achievable with CMYK. Requires thorough cleaning of printing equipment, increasing time and cost.

UV Printing: Used on non-absorbent surfaces like PET or metallic paper, requiring UV light to cure the ink. Higher cost.

8.Lamination:

Gloss Lamination: Adds shine and protection.

Matte Lamination: Reduces glare, adds a high-end feel.

Soft-touch Lamination: Provides a unique tactile experience, often used for premium packaging.

9.Hanging Holes, Hooks, Handles:

Added for functionality. Hanging holes and hooks are for store display, and handles make it easier for consumers to carry.

10.Stickers and Security Seals:

Stickers: Made from paper or transparent PVC, used on product surfaces or packaging.

Security Seals: Void stickers that leave a pattern when removed, indicating tampering.