A Guide to Cosmetic Packaging

When it comes to launching a new product, especially in the competitive cosmetics industry, choosing the right packaging is crucial. Cosmetic packaging not only protects your product but also plays a significant role in attracting customers and conveying your brand’s message. Here’s a comprehensive guide on how to buy packaging for a product, with a focus on cosmetic packaging.

1. Understand Your Product’s Needs

Before you start searching for cosmetic packaging, it’s essential to understand the specific needs of your product. Different cosmetics require different types of packaging. For example:

- Liquids and creams: Require airtight containers to prevent leakage and contamination.

- Powders: Need sturdy, moisture-resistant packaging.

- Lipsticks and balms: Should have twist-up tubes for easy application.

Consider the size, shape, and volume of your product to determine the most suitable packaging options.

2. Identify Your Target Market

Cosmetic packaging should appeal to your target audience. For instance, luxury cosmetics often come in elegant, high-end packaging, while eco-friendly products might use recyclable or biodegradable materials. Knowing your market will help you choose packaging that resonates with your customers and enhances your brand image.

3. Choose the Right Material

Selecting the right material is a critical step in buying cosmetic packaging. Here are some common materials used in cosmetic packaging:

- Glass: Ideal for premium products, it is durable and gives a high-end feel. However, it is heavier and more fragile.

- Plastic: Lightweight and versatile, plastic is a popular choice for many cosmetics. Ensure it’s BPA-free and consider recyclable options.

- Metal: Often used for lip balms and compact powders, metal adds a sleek, modern look.

- Paper/Cardboard: Great for eco-friendly brands, it is often used for secondary packaging like boxes and sleeves.

4. Consider Functionality

Functionality is crucial in cosmetic packaging. Customers should find it easy to use the product. For example:

- Dispensing pumps and sprayers: Perfect for lotions and sprays, they offer controlled application.

- Twist-up tubes: Common for lipsticks and balms, allowing for convenient use.

- Compact cases with mirrors: Ideal for on-the-go touch-ups.

Ensure the packaging enhances the user experience and reflects the quality of your product.

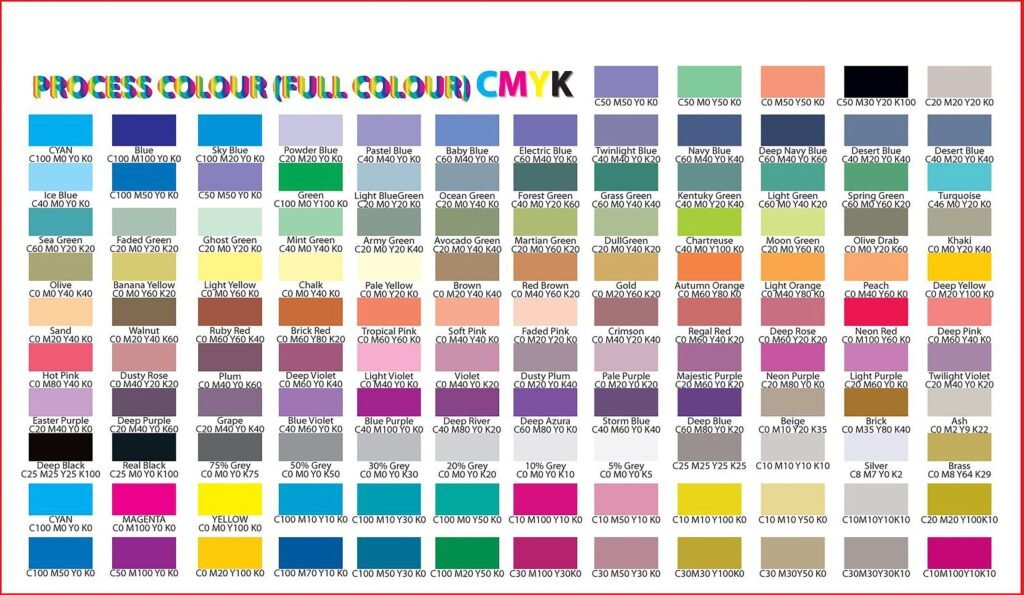

5. Branding and Design

Your cosmetic packaging is a direct reflection of your brand. Invest in professional design to make your packaging visually appealing. Consider the following elements:

- Color scheme: Choose colors that align with your brand identity.

- Typography: Use fonts that are easy to read and reflect your brand’s personality.

- Graphics and imagery: Ensure they are high-quality and relevant to your product.

A well-designed package can attract customers and differentiate your product from competitors.

6. Regulatory Compliance

Cosmetic packaging must comply with industry regulations. Ensure that your packaging meets all legal requirements for labeling, safety, and environmental impact. This includes:

- Ingredient lists: Clearly printed and compliant with local regulations.

- Safety warnings: If applicable, these should be visible and easy to understand.

- Recyclability information: Important for eco-conscious consumers.

7. Supplier Selection

Choosing the right supplier for your cosmetic packaging is crucial. Look for suppliers who offer:

- Quality assurance: Ensure their packaging meets high standards.

- Customization options: To match your specific branding needs.

- Competitive pricing: Without compromising on quality.

- Reliable delivery: Timely and efficient service is essential to meet your production schedule.

8. Ordering Samples

Before making a bulk purchase, always order samples of your chosen cosmetic packaging. This allows you to:

- Test the packaging: Check for durability, functionality, and overall look.

- Ensure compatibility: Make sure your product fits well in the packaging.

- Evaluate customer feedback: Gather opinions from potential customers or focus groups.

9. Plan for Scalability

As your business grows, your packaging needs may change. Choose packaging solutions that can scale with your production volume. Discuss future needs with your supplier to ensure they can accommodate larger orders and provide consistent quality.

Conclusion

Buying packaging for a product, especially in the cosmetics industry, requires careful consideration of your product’s needs, target market, material choice, functionality, branding, regulatory compliance, and supplier reliability. By following these steps, you can ensure that your cosmetic packaging not only protects your product but also enhances its appeal, helping you to attract and retain customers.

Investing time and resources into selecting the right cosmetic packaging will pay off in the long run, contributing to your brand’s success and customer satisfaction.